Planning & Scheduling is an important function of any EAM team. There are several other tasks which depend on planning & scheduling. Managers are interested in knowing how many work orders are generated in a year’s time. Workorders are categorized as either planned or unplanned workorders. Planned workorders are forecasted using a BIRT report Preventive Maintenance Forecasting.

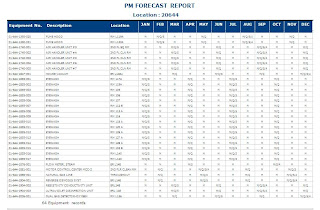

Annual PM Forecasting report shows yearly PM’s for locations and assets. If we pass a location as a parameter it will show assets attached with all the children locations and yearly preventive maintenance plan for each asset and location. It is also possible to estimate labor hrs & cost , material cost and tool cost for these PM’s .Using color codes in this report we can show PM’s which were generated in the past , PM’s which are due and forecasted PM’s .

[ Read More ]

Annual PM Forecasting report shows yearly PM’s for locations and assets. If we pass a location as a parameter it will show assets attached with all the children locations and yearly preventive maintenance plan for each asset and location. It is also possible to estimate labor hrs & cost , material cost and tool cost for these PM’s .Using color codes in this report we can show PM’s which were generated in the past , PM’s which are due and forecasted PM’s .